THE PROBLEM

Many of the senior citizens of America are faced with the need to ration their medicines, due to the exorbitant and ever-increasing cost of their prescription medicines. One way they try to cope with this problem is to buy a supply of pills of double the desired strength, and cutting them into halves. While some pills come with a ‘score’ in the middle, which could facilitate breaking them in halves possible, even when it is done accurately, it is time-consuming, as it is done only one at a time. This is also the drawback of using the single pill cutters that are available on the market. The problem is compounded by the fact that the very people who need to save money by cutting their pills are the elderly, with their fixed incomes, who are also afflicted with physical disabilities such as arthritis and infirmity so that cutting each pill one by one is an extra burden on them.

OUR SOLUTION

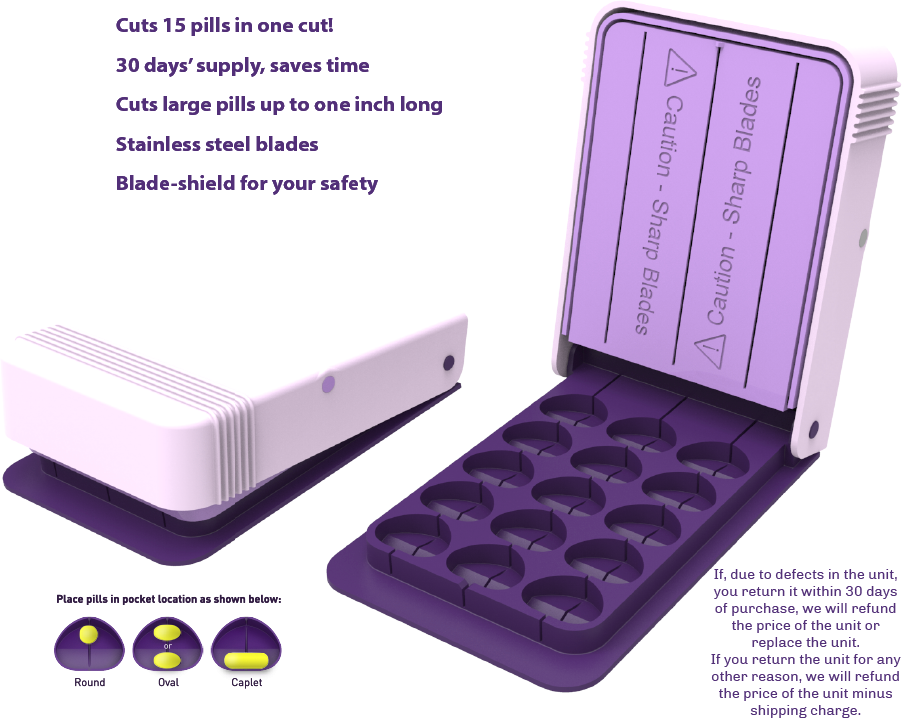

Our “Multiple Pill Cutter” is designed specifically to solve all the above-mentioned problems at once. Since the loading for a whole month’s supply of pills is done fairly easily and rapidly, the time to cut 15 pills is a fraction of the time it takes when using the single-pill cutters. Arranged in three rows of five slots vertically, are specially shaped ‘slots’ for placing the pills to be cut. The round pills and some of the oval pills with relatively rounded edges are placed at the narrow front ends of these slots and the caplets (the elongated pills) and other oval pills with relatively straight edges are placed at the straight base of these slots. The floor of these slots are specifically and differently designed for round pills versus caplets, to help align the respective kind of pills to the center so that the cut halves are substantially equal. By using gravity to help the pills align further towards the center, helps this alignment process significantly.

THE PILL CUTTER

THE PILL CUTTER UNIT, CLOSED

THE PILL CUTTER UNIT, OPEN

THE POCKETS FOR PILLS

SAMPLE PLACEMENT OF DIFFERENT TYPES OF PILLS

THE PLACEMENT OF ROUND PILLS FOR CUTTING

THE PLACEMENT OF CAPLETS FOR CUTTING

CUT HALVES (CAPLETS)

THE CUTTING PROCESS

LOADING ROUND PILLS

The round pills and the oval pills with substantially rounded edges are placed at the front (near the hinge) end of the multiple pill cutter, as shown in the figures below:

The alignment is aided by tilting the hinge end of the pill cutter down forwards, so that the pills will tend to move towards the triangular front end of the pockets. Gentle taps at one side of the pill cutter, with the unit tilted down will aid this alignment. Further refinement can be made by visually inspecting the alignment and making finer adjustments. If care is taken in this alignment, and with some experience, one can get fairly adept at cutting pills accurately into equal halves.

LOADING CAPLETS

The caplets (elongated pills) and oval pills with substantially straight sides are placed in the flat base (the part facing the open end of the pill cutter) of the pockets. Please see the figures below for guidance:

Just like aligning the round pills as stated above, the caplets are carefully placed touching the base of the pockets and the alignment is aided by gravity by tilting the pill cutter towards the open end that is facing the user, and then gently tapping the side of the unit. Further refinement of the alignment is made by visually inspecting and making fine adjustments. Again, if care is taken, and with experience, substantially accurate alignment can be accomplished and the caplets can also be cut accurately into equal halves.

THE CUTTING PROCESS

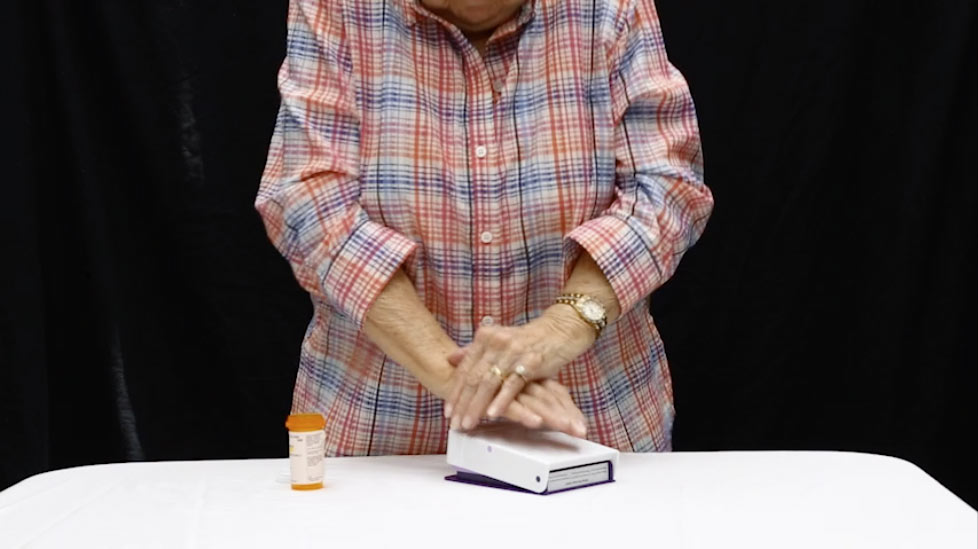

After proper loading of the pills in their respective positions in the pill pockets, and inspecting for accurate alignment with respect to the midline of each pocket, the pill cutter unit is gently placed on a hard surface. Then the lid is lowered, again gently, so as not to disturb the alignment of the pills. After that, the cutting process is accomplished as shown in the figure below by pushing down on the top of the lid by aligning the weight of the operator through the bases of the palms. Please refer to the figure for the correct procedure. The videos also demonstrate these processes. When the pills are cut, you will hear a sharp snapping noise; this is due to the cutting process, which is actually a splitting of the outer top part of the pills; the pills are not actually cut through like in a sawing process.

UNLOADING THE CUT HALVES

After the pills have been cut, the best way to unload the cut halves is by gently tilting the open pill cutter towards one side, as shown in the figure below. The halves will readily fall off with the aid of gravity, onto a receiving surface/container. Please refer to the figure below and the videos for the unloading of the pills:

SOME SPECIAL INSTRUCTIONS

(Best results are obtained when the alignment of the pills is done accurately)

1) Do not mix different types of pills for cutting; this will avoid cross-contamination of the medicines.

2) Do not use this pill cutter to cut capsules (the pills with soft gelatin-covered shells).

3) Cuts pills as long as one inch.

4) To cut the tiniest of pills, please use only the first two or three rows near the open end of the pill cutter. The reason is that the blades may not reach these tiny pills in the pill pockets near the hinge of the unit.

5) Rarely, pills that are soft and chalky (these pills do not have the usual coating on their surface), may tend to crumple when one tries to cut in all 15 pill pockets. One solution is to use only two or three rows close to either the hinge or the front of the unit; then, the pills will be cut cleanly.

6) Please clean the pill pockets after each cutting operation by gently tapping on the unit after tilting it upside down and, further clearance by blowing on the pockets or with the use of a brush or Qtips. No other maintenance procedure is needed. The stainless steel blades are expected to last the life of the unit.

Multiple Pill Cutter users write:

"The 30 Day Pill Cutter works incredibly well; regardless of the size of the pills, it cuts easily and cleanly," So writes Paul Cosand. He continues: "This pill cutter works better than any other pill cutters that I have ever used! This is a device that everyone should have if they have to cut any pills in half. Thank you for inventing such a wonderful device!"

Sophia Trevino writes: "I was slow in using this product, when my daughter bought it for me, because of my age I am just not good with change. " She continues, "But when I finally used the Multiple 30 Day Pill Cutter, it saved me so much time and effort that I wish I hadn't hesitated in using it. It is easy to use and a great time saver for those of us who have to cut pills on a monthly basis. Most importantly, it is very well made and safe to use. I am very grateful that this product exists and I highly recommend it."